A Case Study in Going Above and Beyond for Our Customers

Our precision machine shop is committed to personal service, which we believe is a step (or a few) beyond standard customer service.

As experts in wire EDM, waterjet cutting, and precision machining capabilities, we take every opportunity to share our knowledge and skills with our customers—especially those we’ve formed deep relationships with over the years.

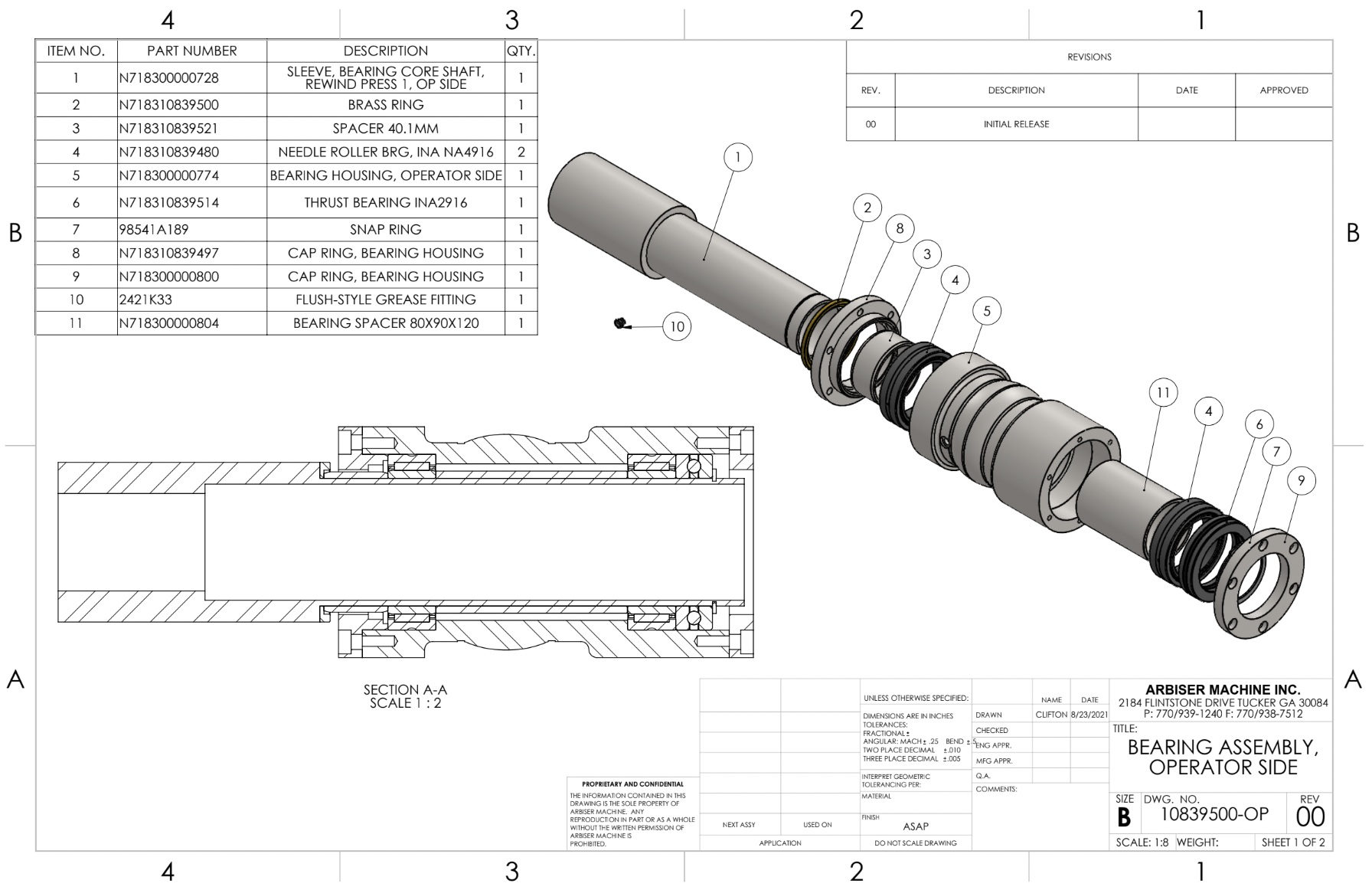

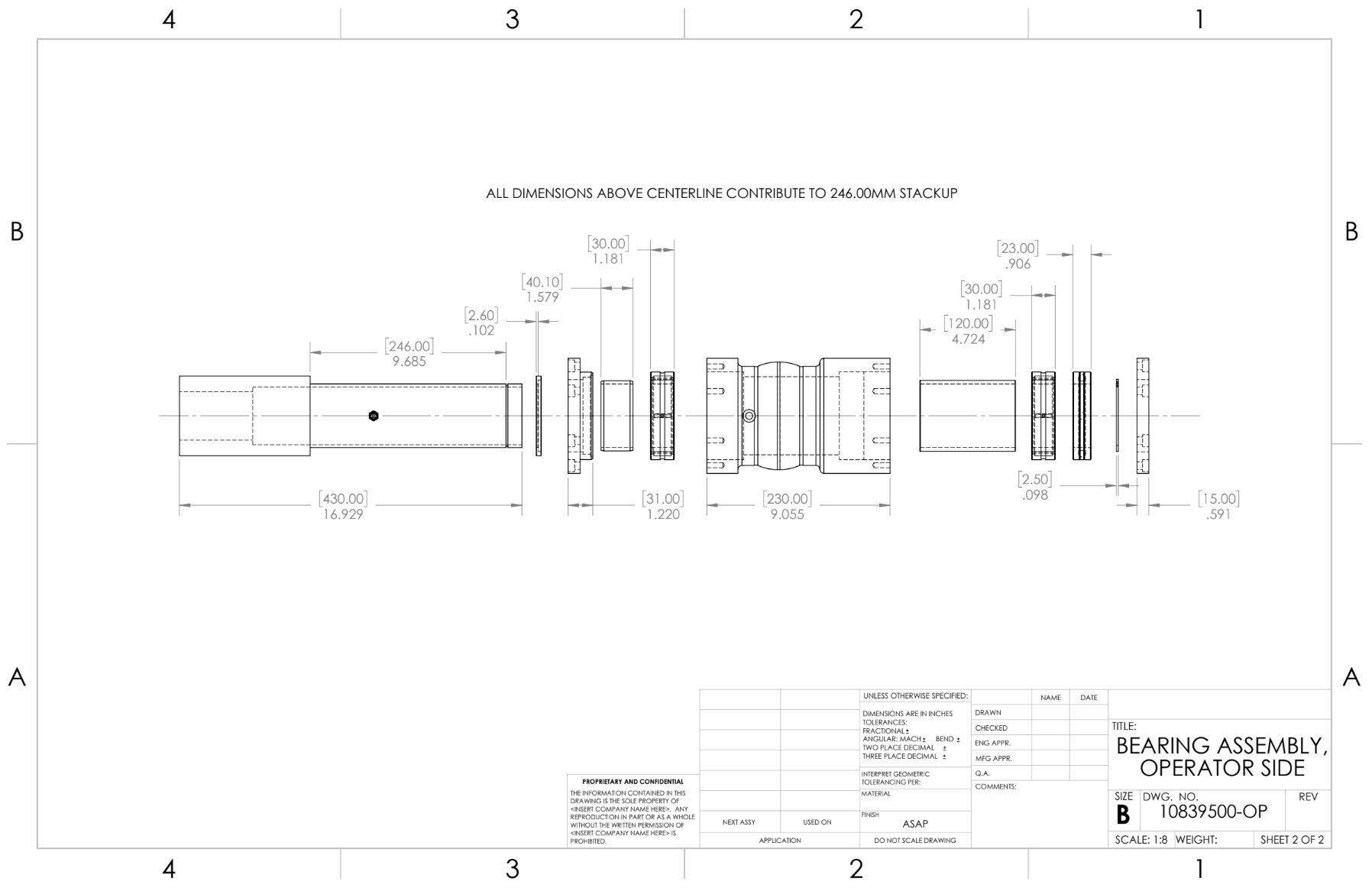

Recently, we were thrilled to help one of our best customers transform a messy, vague, and inaccurate sketch into a robust, detailed, and useful drawing that correlates with a clear bill of materials.

What They Sent Us

Our customer came to us with a hand-sketched assembly drawing for a portion of a printing press and told us they needed some replacement. They’d been using this drawing to manufacture their parts for years, but it was nearly impossible to read from an engineering perspective.

The drawing lacked critical indicators of size and scale, and some of the part numbers and descriptions were incorrect. It was so difficult to interpret that a previous manufacturer actually assembled the parts with two of the bearings in backward, compromising the fit and function of the assembly.

How We Saved the Day

We knew it would be impossible to manufacture the parts our customer needed using only their drawing, so we hoped they’d be able to provide a sample for us to work from. When we realized that the sketch they’d given us was all they had, we decided to do them a favor and create a comprehensive drawing and bill of materials as we discussed the project, addressing fit issues as we went along.

When looking at our drawing compared to their initial sketch, the differences are obvious:

Our drawing labels each part in the sub-assembly clearly, assigning a correct part number

Our drawing depicts which parts belong on the inside and outside of the assembly

Our drawing includes missing pieces from the drawing, which we indicated as parts 8, 9, and 10

Our drawing has helpful size and scale indicators

Why Did We Do It?

It would have been easy for us to no-quote this project or attempt to build the part to print and call it a day. But doing the bare minimum of what’s expected just isn’t who we are.

Instead, we strive to make our customers’ lives easier by making their manufacturing processes better and more efficient.

The drawing we returned to our customer creates efficiencies on their end and ours. Now that everything in the drawing is clearly labeled and identified, it serves as a catalog that can be used in tandem with their bill of materials when it comes time to order a part for the assembly. They also now have a comprehensive training tool that they can use to explain the assembly to new employees.

If you’re ready to build a deep, lasting relationship with your manufacturer, request a quote from our precision machine shop today!