4 Must-Have Details for 2D Part Drawings

Customers want their parts as quickly as possible—and Arbiser Machine is here to deliver. We always go above and beyond to meet our customers’ strict deadlines, but that can prove challenging when we don’t have all the information we need to start a project.

When we receive drawings with incomplete information, we have no choice but to add extra steps to our own process and/or contact customers to find what’s missing.

We’d rather hit the ground running! Be sure to include these details in your 2D drawings so we can turn around your parts as quickly as possible.

Include These Details with 2D Part Drawings

1. Part numbers

Many of the drawings we receive include vague descriptions like “Flange 1” or “Shaft 2” in place of actual part numbers. But when a drawing is missing a part number, we’re left to create one on our own.

This extra step isn’t as simple as you might think. First we need to cross-check with our records to ensure that we’re not duplicating any part numbers. Then we need to run the part number by the customer to ensure it doesn’t conflict with any of their records.

While we love a chance to catch up with customers, this back and forth creates unnecessary delays in getting a project started. It’s much faster if we can receive a drawing that includes part numbers up front.

2. Revision numbers

Revision control is critical to the success of our internal processes—and to maintaining consistency on the customer side. We prefer to use whatever system our customers have developed for revision control—but that relies on us receiving accurate revision numbers on drawings.

When we know for certain which revision we’re working on, it ensures that we’re aligned with our customers on manufacturing the most up to date version of their part.

If this information is missing, we’ll use our own date-based system for internal revision control. However, that system may not translate back to the customer’s own internal operations, which can lead to continued back and forth about which revision is the most current. When in doubt, opt for a simple alphanumeric system—and add a revision number every time.

3. 3D CAD models and PDF drawings

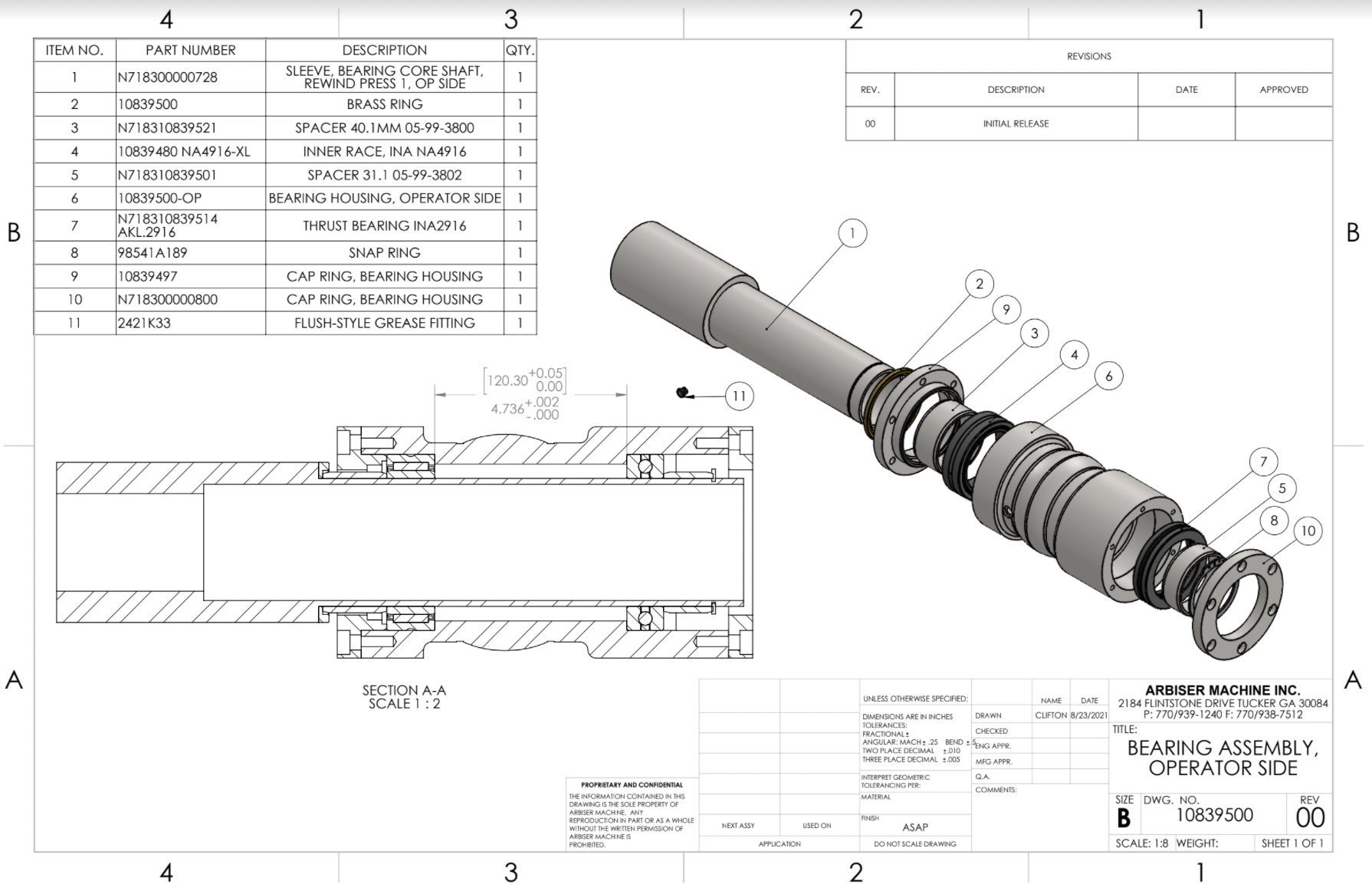

It’s important for us to have both a 3D CAD file and a 2D PDF drawing for each part or assembly we work on.

We use the 3D CAD model to provide fast and accurate quotes to customers, but this file is often missing critical information. 2D drawings are crucial because they show us the explicit tolerances and dimensions, which are key for proper assembly.

Our engineers will create 2D drawings based on customers’ CAD files if necessary, but this process can add up to a week to the project’s lead time. The 2D drawing is usually on file, so make sure to include it with your initial RFQ.

4. Critical tolerances

Drawings must include critical tolerances. This data serves as our most important reference point for confirming that a part will function as intended.

Occasionally we receive drawings that indicate in writing how the part should function. While this information provides some context, it’s too qualitative on its own. Our machinists need precise numeric tolerances so they can machine parts exactly to your specifications.

Whether you need wire EDM services, waterjet cutting services, or CNC milling services, we always request explicit tolerances so that we have a clear understanding of what exactly is considered in spec.

A quick note on quantity. . .

Now that we’ve reviewed what details you should include with your drawing, let’s quickly discuss one detail you shouldn’t include with your drawing.

Indicating the part quantity on your drawings is unnecessary—and it can even cause confusion for future customer orders. Why? Because if an initial drawing depicts a part quantity of X but a customer asks us to cut a quantity of Y a few months later, the drawing will still show a request for X parts. And that can lead to confusion and, yes, more back and forth and delays in getting started.

As always, we’re on your side and will do everything we can to ensure you get the highest quality parts as quickly as possible. Request a quote to work with us!