What Is 4-Axis Wire EDM?

Do you remember playing with a Play-Doh Fun Factory as a kid? You’d put the Play-Doh in one end of a tube, and it would come out the other end as a fun shape. It’s similar to using an icing tip to decorate a cake.

Most people are familiar with extrusion tools—the icing tip, the Play-Doh tube—but probably haven’t put much thought into how these parts are made.

The answer, in many use cases, is with 4-axis wire EDM, a manufacturing method used to accomplish geometries that differ from one end of a part to the other with a gradual transition.

How Does 4-Axis Wire EDM Work?

During the traditional wire EDM process, upper and lower guides control the wire position. These guides hold tiny precision guide tubes that contain the wire during cutting to ensure extreme accuracy. Both guides move in identical directions, keeping the wire perfectly straight as it cuts away the material.

4-axis wire EDM allows the two guides to move in different directions. For example, the upper guide may move in a circular motion while the lower guide moves in a square motion, ensuring a gradual transition between the shapes. It sounds complex—and it can be—which is why it’s essential to work with an experienced wire EDM manufacturer with the right capabilities, software, and wire types to offer 4-axis wire EDM services.

4-Axis Wire EDM vs. Precision Machining

4-axis wire EDM is capable of certain techniques that you won’t get with precision machining. In many cases, machining methods like CNC turning and CNC milling can’t achieve the same geometric complexities as 4-axis wire EDM.

CNC Turning. A lathe might be an option if a part has similar geometries on its external and internal surfaces. For example, this precision machining method could create a cylindrical part with a funnel inside. But if a part design shows a round internal geometry and a rectangular external geometry, we’d use 4-axis wire EDM services instead.

CNC Milling. A mill can do the job if the features are large enough. But consider, for instance, the sealing function on a Ziploc bag, which has intricate geometries that are too small for CNC milling to achieve. We commonly rely on 4-axis wire EDM for our packaging customers.

In theory, it’s possible to use precision machining to make two separate parts with different geometries, then weld them together as a workaround. However, it’s difficult to accomplish a gradual transition between the shapes without wire EDM services, and an abrupt transition would likely affect the functionality of the part.

Common Applications for 4-Axis Wire EDM

4-axis wire EDM is an efficient way to create complex parts with high precision. In addition to extrusion tools, here are some of the other parts we commonly make using this capability:

Wrapping tools. We use 4-axis wire EDM to make tools used to wrap a coating around an object. This method allows us to achieve the tapered effect and the small notch at the end of the tools.

Molds. Mold applications that involve bringing two parts together require high-precision tapers to ensure a tight fit during assembly. 4-axis wire EDM is the perfect method for cutting those tapers.

Electrical connections. When creating tapered dovetail pieces that need to come together, 4-axis wire EDM may be the only tenable solution. The features are often too thin for precision machining and have differing geometries from one side of the part to the other—perfect for 4-axis wire EDM.

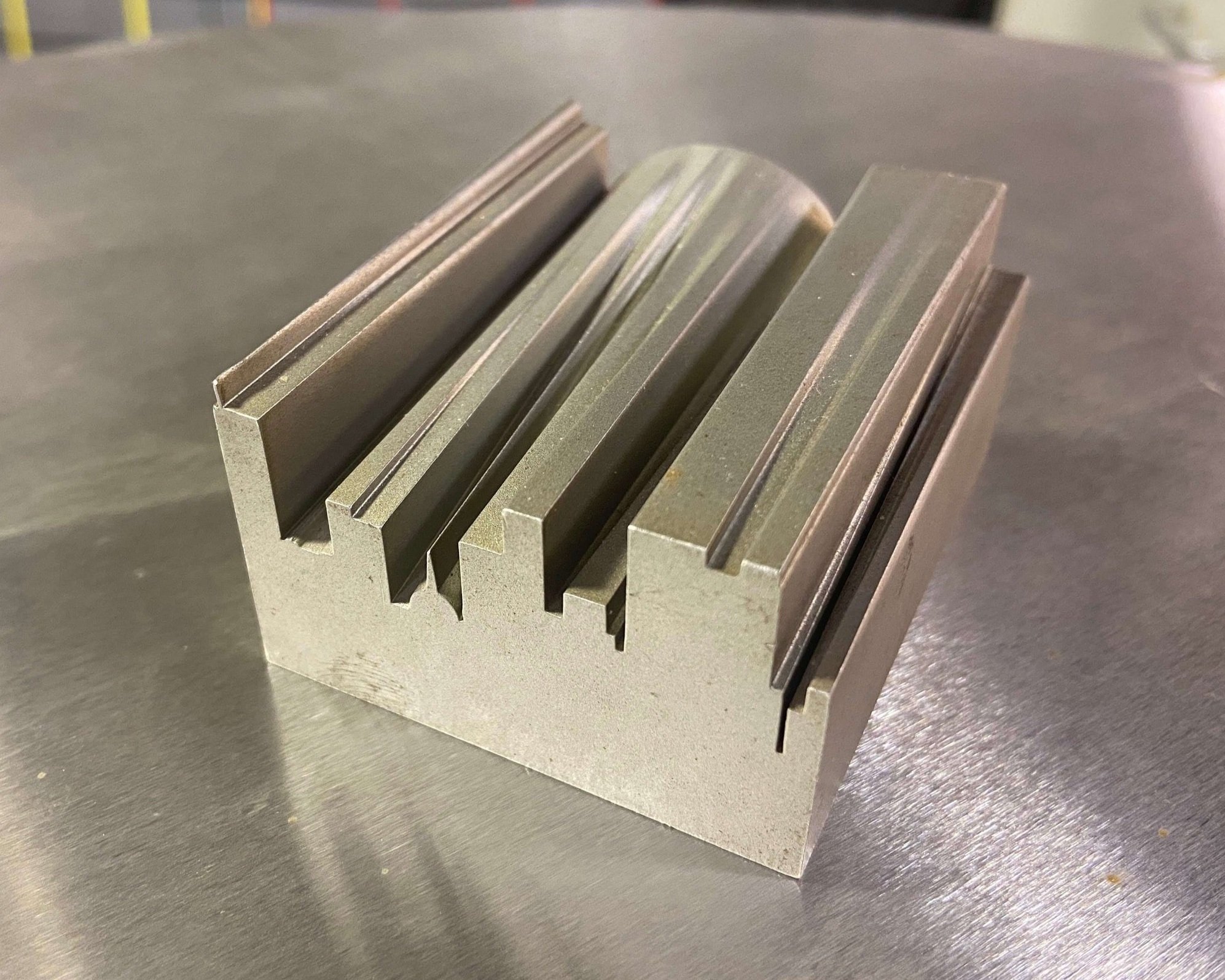

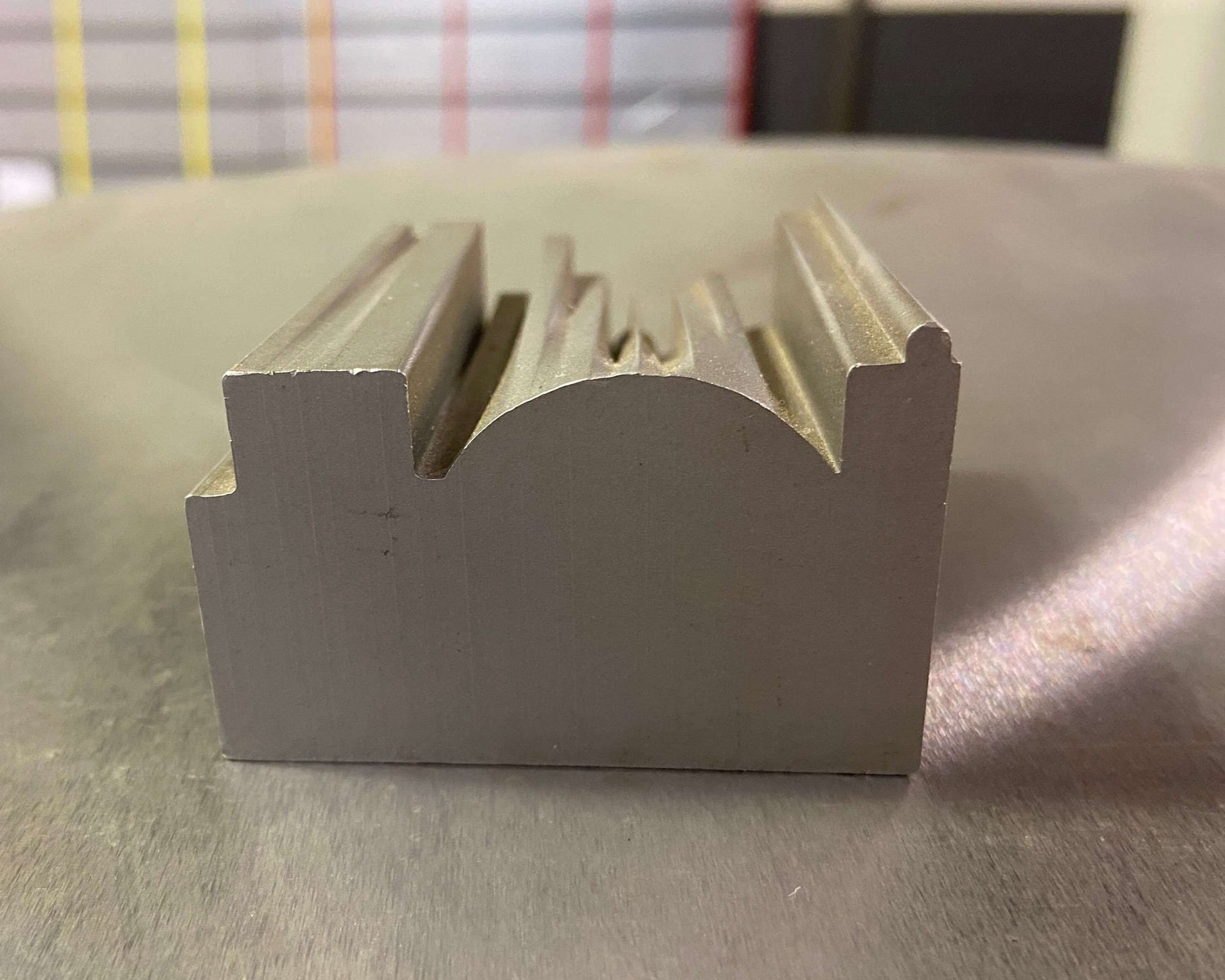

Want a visual of what 4-axis wire EDM services can do? Check out these images of one of our favorite 4-axis wire EDM projects. This part features the Atlanta skyline on one end, with a sunrise on the other. Pretty cool, right?

At Arbiser Machine, we know that not every part has simple geometries. We’re proud to offer services like 4-axis wire EDM to meet all of our customers’ needs. Request a quote today, and put your next project in our capable hands.